Cutback SC 800

| CHARACTERISTIC | CUTBACK SC 800 | TEST METHOD | |

|---|---|---|---|

| Min | Max | ||

| Kinematic Viscosity at 60°C (140°F) mm2/s | 800 | 1600 | ASTM D2170 |

| Flash Point (Tag Open-Cup) °C | 70 | – | ASTM D92 |

| Distillation Test : | |||

| Total distillate to 360°C (680°F) % vol | – | 15 | ASTM D402 |

| Solubility in Trichloroethylene % | 95 | – | ASTM D2042 |

| Kinematic Viscosity residue at 60°C (140°F) mm2/s | 1000 | 16000 | ASTM D2170 |

| Asphalt Residue : | |||

| Residue of 100 Penetration % | 60 | – | ASTM D2170 |

| Ductility 100 Penetration residue at 25°C (77°F) cm | 50 | – | ASTM D2170 |

| Water % | – | 0.5 | ASTM D95 |

Description:

Rapid Curing 800 SC800 combination of penetration grade asphalt cement and a diluent or cutter highly rapid in its volatility making

it easier to apply. Cut back SC800is compliant with ASTM standard for cut back asphalt.

SC800grade is used in the construction of roads and highways and

for treatment for pavements in compliance with ASTM. SC800is also commonly used in spraying and for applications of mixing.

Safe Handling and Storage Of SC800:

Use Personal Protective Equipment (PPE’s) when handling (i.e. gloves, eye protectors, etc.)

Maintain safe heating temperatures when using this product

Avoid contact with skin, eyes, and clothing

Avoid breathing vapor, spray or mists when applying.

SC800Storage:

Keep drums in a cool, well-ventilated place.

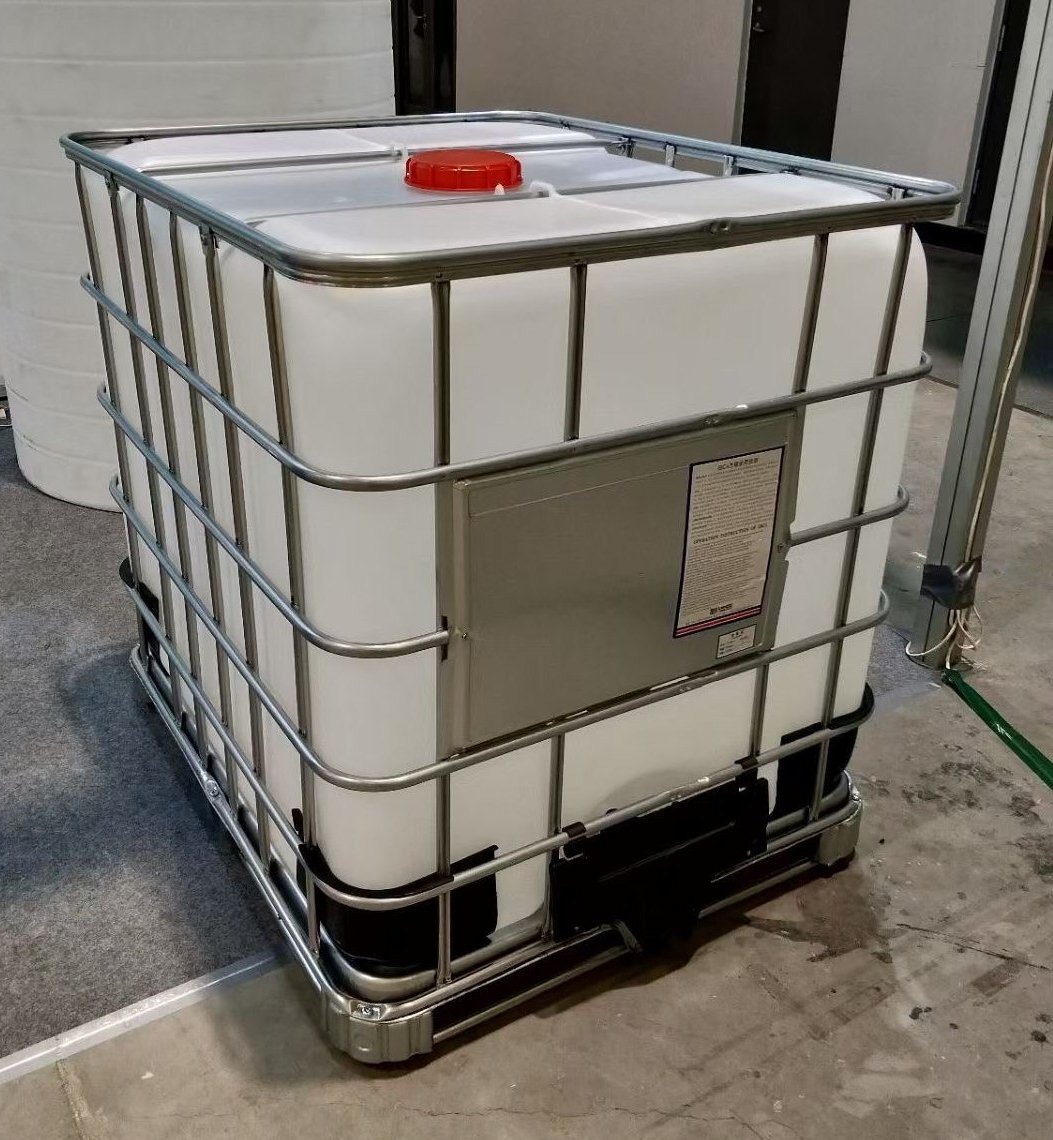

SC800Packaging:

SC800Packing is available in 1mm thickness steel drums or PE drums 200 KG Net Weight and 210 KG Gross Weight. It is also available in IBC containers.