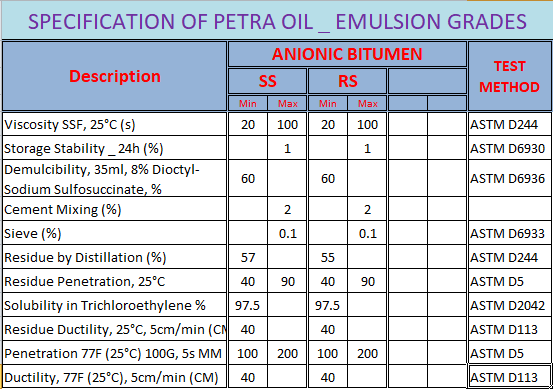

ANIONIC BITUMEN

Description:

Penetration Graded Bitumen Anionic is high-quality asphalt, derived from crude petroleum refining. It is dark in color and possesses waterproofing and adhesive properties. It is substantially non-volatile and softens gradually when heated.

Bitumen Anionic is commonly used for the production of hot mix asphalt for the base and wearing courses. a thinner pavement design Usage: The main common usage of bitumen Anionic is being used in the manufacturing of hot mix asphalt for the base and wearing courses. Due to its high level of viscosity, it enables a thinner pavement engineering design and an overall 30 percent reduction in the amount of asphalt being applied.

Safe Handling and Storage:

Use Personal Protective Equipment (PPE’s) when handling (i.e. gloves, eye protectors, etc.)

Maintain safe heating temperatures when using this product

Avoid contact with skin, eyes, and clothing

Avoid breathing vapor, spray, or mists when applying.

Storage:

Keep drums in a cool, well-ventilated place.

Packaging:

Penetration graded Bitumen Anionic is available in 0.6 mm thickness, 180 kg net weight drums, 95 cm height and 45 cm diameter (+/- 3 kg operational tolerance)